Traditional processes to solve metal wear or surface scratch technical measures

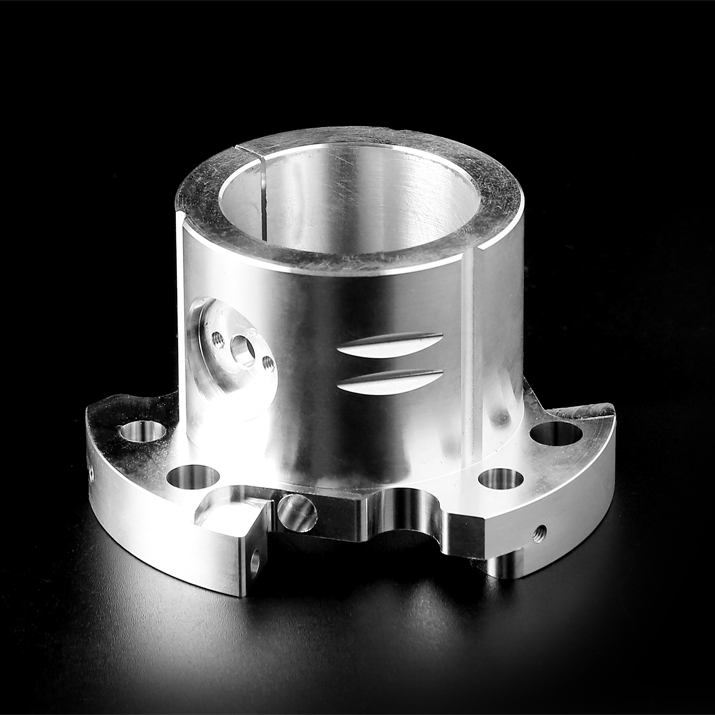

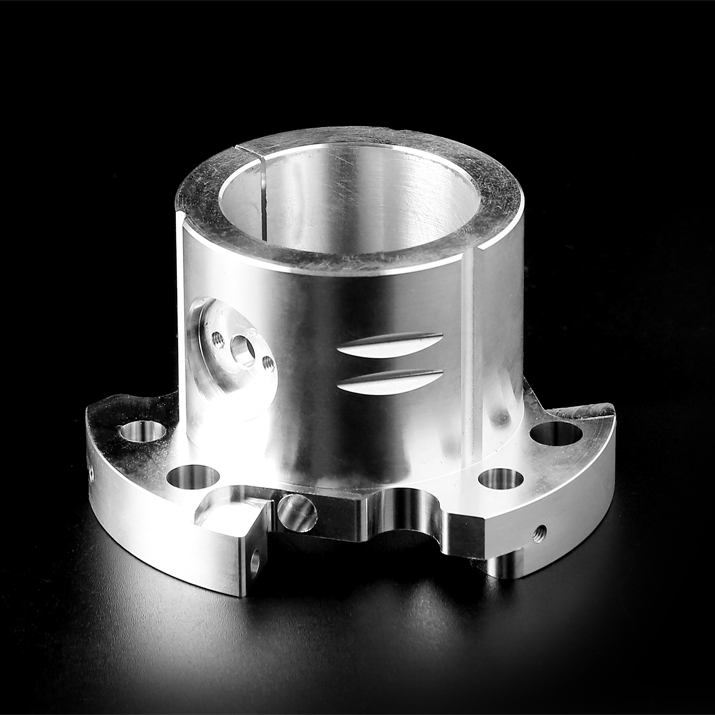

(1) Repair welding + processing: This repair method is one of the most traditional process methods to solve metal wear and scratches, and such repair processes have inevitable repair defects. a. The welding process has a thermal stress effect on the metal, which is easy to damage the equipment twice; b. Due to the problem of welding accuracy, the repair part after welding is more difficult to operate during machining or fitter recovery size; c. The parts after welding repair and repair are very easy to deform, which affects the running accuracy of the equipment. (2) Brush plating repair: This process method can be used for the repair of minor defects such as local scratches or surface wear, and the biggest disadvantage of the brush plating repair process is a. The surface is brushed as a whole, and the local scratches or defects in the middle part are not easy to operate, and the repaired part has the problem of delamination or poor combination with the original metal material; b. The repair process can only be used for metal wear with a wear depth of less than 0.3mm, and the repair range is greatly limited. Technical measures for carbon nanocoatings to solve all kinds of metal wear or surface scratches The application process of carbon nanopolymer materials is very simple and convenient, after the analysis of operating environmental parameters, according to a certain construction process for wear or scratch repair, commonly used repair processes are as follows: a. Machining repair process: this process is to use carbon nanopolymer materials to first restore the worn or scratched parts, and use the machining method to process the dimensions of the repair materials to ensure the shape and position tolerance requirements of shaft parts or other parts; b. Component correspondence repair process: use the mutual cooperation relationship of the original components during the operation of the equipment to complete the online repair technology of the wear part. This repair process can ensure the effective mating surface of the two parts to the greatest extent, far exceeding the contact surface between the original metal and the metal; c. Tooling mold repair process: make the corresponding repair tooling according to the original design drawing size of the parts or the actual size measured on site, and complete the repair of the wear part in combination with the application characteristics of carbon nano repair materials, which can well ensure the shape and position tolerance requirements of shaft parts. Industrial carbon nanopolymer repair technology is similar to a cold welding technology, its advantages are excellent compressive resistance, corrosion resistance and thermal alternating resistance, while having high chemical stability and good physical and mechanical properties, can be firmly bonded to the metal surface and not easy to fall off. There will be no high temperature during the online repair process, which protects the equipment body from damage and is not limited by the amount of wear during the repair process. Dongguan ganzoo Prototype Manufacturing Co., Ltd. has more than ten years of CNC Machining experience, and has deep accumulation in various metal specific projects such as aluminum alloy precision parts processing, automation Equipment parts processing, etc. It is a solution provider focusing on prototypes, high-precision parts, molds, on-demand manufacturing and other one-stop services. Is an expert in New Energy Solutions,New Solar Technology,CNC machining If you are interested in our service or need any technical support, welcome to contact us Ms.Becky+(86)13006687216, we are happy to share our understanding of New Power Energy with you and provide solutions for your economy new solar technology.